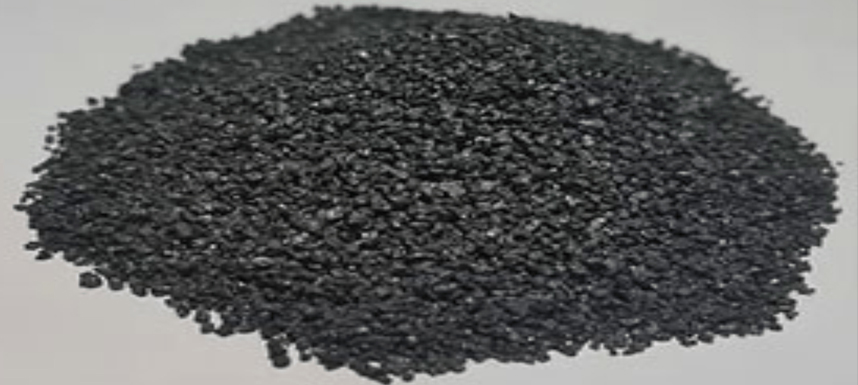

Nozzle filling compound is a specialized refractory material used in the steelmaking industry. It is designed to fill and seal the nozzle of a ladle or tundish during continuous casting processes. The compound serves several critical functions, including preventing molten steel from leaking out of the nozzle, maintaining consistent flow rates, and reducing nozzle clogging or erosion. Typically made from a blend of refractory aggregates, binders, and additives, nozzle filling compounds are engineered to withstand high temperatures, thermal shock, and chemical corrosion, ensuring smooth and efficient steel casting operations.

-

Call Now +91-8878855539